"Flavor—encompassing both aroma and taste—provides the defining characteristic of how we experience food. Flavor has long been an enigma to scientists: Aristotle described two categories of taste, sweet and bitter. Today we recognize five basic tastes in food: sweetness, saltiness, sourness, bitterness and umami (savory). But what are the scientific components of flavor, and how can flavor be studied, quantified and replicated?"

American Chemical Society (2013, August 29). Flavor chemistry research: USDA ARS Western Regional Research Center. Washington, D.C.: American Chemical Society. https://www.acs.org/content/dam/acsorg/education/whatischemistry/landmarks/usda-flavor-chemistry/flavors-brochure.pdf.

The effort to identify the specific components of flavor and to quantify its most essential elements in replicable ways was the focus of an assortment of U.S. Department of Agriculture (USDA) chemists located in the Western Regional Research Center (WRRC) in the middle of the twentieth century. Recent studies from the USDA's Agricultural Research Service (ARS) document its work to study the flavor of various foods such as tomatoes, orange juice, beans, and catfish. But the systematic effort by USDA to carry out studies of the basic chemical nature of food and its nature as a flavor containment and delivery system is rooted in a specific era in the 1900s. This short review of flavor research at the ARS is centered on this period. It will also feature historical materials held by the National Agricultural Library on taste, flavor, and the effort to study these enigmatic phenomena in ways that benefit producers and consumers.

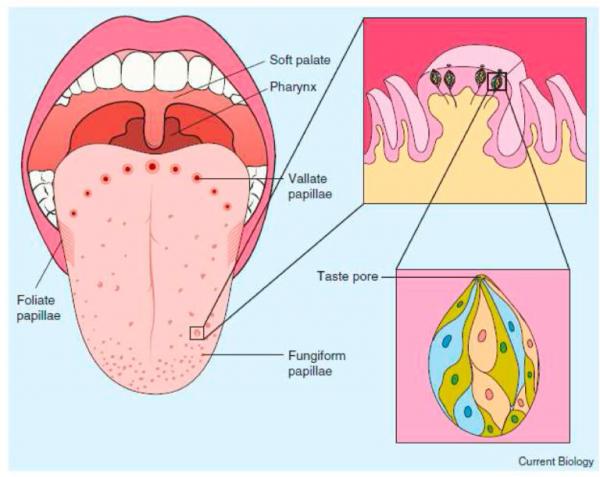

“Taste papillae and taste buds of the human tongue” by Charles Pence is licensed under CC BY 4.0.

Pence, C. (2022). The tongue map and the spatial modulation of taste perception. Current Research in Food Science, 5, 598-610. https://doi.org/10.1016/j.crfs.2022.02.004

What is Flavor?

“Flavor impressions are surprisingly complicated and multidimensional. They are driven principally by the recognition of taste substances by the taste buds, the sensing of aromatic substances in the nose, the way the food feels in the mouth, and chemical effects on the mucous membranes (chemesthesis).”

p. 2

Mouritsen, O.G. & Styrbaek, K.(2017). Mouthfeel: How texture makes taste. New York: Columbia University Press.

If this definition seems a bit vague, bordering on circular, that can be seen as a reflection of the complexity of flavor science. Often, the words flavor and taste are used interchangeably, as synonyms, and as a way to define each in terms of the other (i.e., flavor is something that is perceived through taste and taste is what occurs when a flavor is perceived).

For example, the International Organization of the Flavor Industry defines a flavoring as “an ingredient whose primary purpose is to provide taste” (n.d.). The quote from the American Chemical Society that opens this essay asserts that taste is an element of flavor but does not explain where one concept ends and the other begins. Finally, in 1937 Ernest C. Crocker summed up the then-consensus view among mainstream chemists when he wrote, “flavor has been defined as that property of a food or beverage that makes it excite the senses of taste or smell” (p. 273).

The central problem is one of creating a clear and accurate definition of the flavor concept, and then to operationalize this definition in terms of variables that can be observed and measured empirically. Looking to the word “taste” to function as a shortcut around this task will not work. As Spence, Smith, and Auvray observe, defining the concept of taste poses exactly the same problem as that arising from the concept flavor. “Starting with the term ‘taste’ and to what it refers to in a food context, there are several possibilities: 1) Taste (or tastes) as qualities of the foods or liquids we consume; 2) Taste as the sense we use to discover these qualities; 3) Taste (or tastes) as the characteristic experiences generated by that sense when we eat or drink” (2014, p. 4). So we end up in exactly the same place: with a complex phenomenon in need of clear explanation that does not rely entirely on a synonym as a definition.

Most current definitions of flavor take a more holistic view of the construct and the degree to which it has to be understood as a product of multiple factors. The International Organization for Standardization defines flavor as the “complex combination of the olfactory, gustatory and trigeminal sensations perceived during tasting. Note: the flavour may be influenced by tactile, thermal, painful and/or kinaesthetic effects” (2015). Mouritsen recognizes predictable variation across academic disciplines. “For the natural sciences, the key concept is flavor encompassing all physical, chemical, and neurophysiological aspects. For researchers in human sciences, psychology, anthropology, and social sciences, taste is a broader concept related to tradition, geography, culture, as well as social relations. For cooks and practitioners, taste is a multimodal facet of food and the way we perceive and enjoy it” (2015).

Perszyk, Stewart, and Roland expand upon this trend and go one step further by defining taste in a similarly helpful way. “Flavor comprises combined elements of olfactory (i.e., retronasal odor), somatosensory (e.g., texture and temperature), and gustatory sensations that attend ingestion. In contrast, taste refers exclusively to the perceptions and behaviors that arise when chemical components of food stimulate the gustatory apparatus of the oral cavity, namely taste receptor cells found within taste buds” (2019).

Finally, one more definition will help to contextualize the work of the Western Regional Science Center. Gordon M. Shepherd is credited with coining the term “neurogastronomy” as a means for modeling this more complex view of flavor (2006). In a later piece Shepherd argues that “flavour science is concerned with the sensory appreciation of food. However, flavor is not in the food; it is created by the brain, through multiple sensory, motor, and central behavioral systems. We call this new multidisciplinary field ‘neurogastronomy'” (2015).

This assertion about the placement of flavor in the brain and not in the food is a useful way to understand the work of the ARS Western Regional Research Laboratory, now Center, in Albany, California, just north of Berkeley, and why its historical significance arises from how its scientists measured flavor. The early work of the Laboratory was focused on measuring the specific chemical flavor components “in the food” thought to determine how they were perceived when eaten. The ways in which they made these measurements will be addressed next.

The Start of the Western Regional Research Laboratory: The Foundations of Flavor Research

“Four regional research laboratories are being built by the United States Department of Agriculture. They will be known as the Northern, Eastern, Southern, and Western Regional Research Laboratories, located at Peoria, Illinois; Wyndmoor (Philadelphia), Pennsylvania; New Orleans, Louisiana; and Albany, California, respectively. The program of research for these laboratories is directed toward the discovery and development of new and wider uses, and extended markets, for agricultural commodities and their products and byproducts, especially those that are subject to surplus conditions.”

Hanson, R.L. (1940). Description of regional research laboratories. U.S. Department of Agriculture. Bureau of Agricultural Chemistry and Engineering. ACE-33. https://archive.org/details/descriptionofreg33hans.

Some of the most historically significant work of the Western Regional Research Laboratory related to the ways in which their scientists measured flavor elements in food. The initial mandate for the Laboratory was to study food preservation techniques that could be used to alleviate a then-pressing food surplus problem and help farmers recover from the effects of the Great Depression. The Agricultural Adjustment Act of 1938 authorized the creation of four USDA research laboratories “one in each major farm producing area, and, at such laboratories, to conduct researches [sic] into and to develop new scientific, chemical, and technical uses and new and extended markets and outlets for farm commodities and products and byproducts thereof. Such research and development shall be devoted primarily to those farm commodities in which there are regular or seasonal surpluses, and their products and byproducts.”

In 1941 Wallace B. Van Arsdel, the chief of the Engineering & Development Division of the Western Regional Research Laboratory explained the factors behind the new unit’s mission. "It is generally agreed that three major factors have operated to bring about surplus conditions–the decline of foreign trade, advances in science and technology, and widespread unemployment” (p. 1). A more prophetic note about the role the facility would play was sounded at the laying of its cornerstone when USDA Secretary Henry Wallace said, “‘it is a comforting thought…to know that this great research laboratory . . . and the other three that are under construction . . . could be turned into research institutions for national defense should the occasion demand” (Finlay, 1990, p. 48). Indeed, as a history of the laboratories states, ‘the four regional laboratories had been in operation for only about a year when, on December 7, 1941, Japan attacked Pearl Harbor. On December 8, the United States declared war on Japan, and the goals of the researchers were soon altered to meet urgent needs of the military'” (Kelley, 1993, p. 5).

At their conception, these four regional laboratories were expected to engage in sound scientific work that would be responsive to the current needs of the American people, whatever they might turn out to be: Great Depression-induced agricultural surpluses or World War II-driven food shortages and an urgent need for military rations.

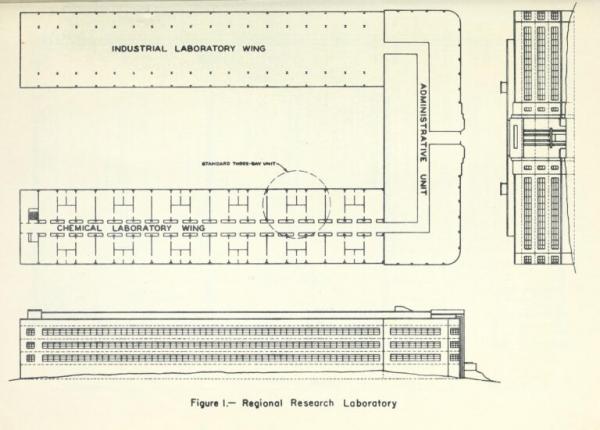

Western Regional Research Center Building

Figure showing layout of standard design of the four regional research laboratories. Hansen, R.L. (1940). Description of regional research laboratories. Bureau of Agricultural Chemistry and Engineering. U.S. Department of Agriculture. ACE-33. https://archive.org/details/descriptionofreg33hans

The initial assignment for the Western Regional Research Laboratory was to study the following food commodities, given its proximity to the farming operations in California:

- fruits

- vegetables

- alfalfa

- wheat

- poultry

A later piece of legislation, the Research and Marketing Act of 1946 added rice, wool, sugar beets, and dried beans and peas to its portfolio of projects (U.S. Department of Agriculture. Agricultural Research Administration. Bureau of Agricultural and Industrial Chemistry, 1949).

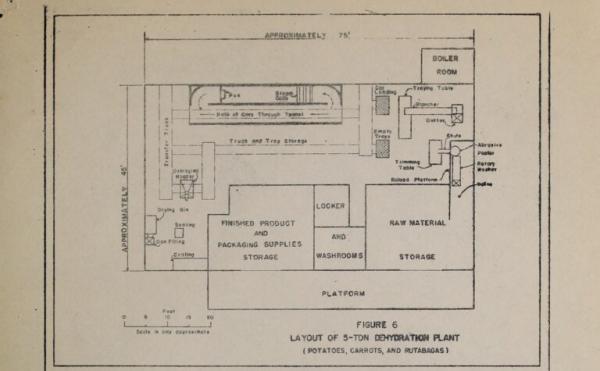

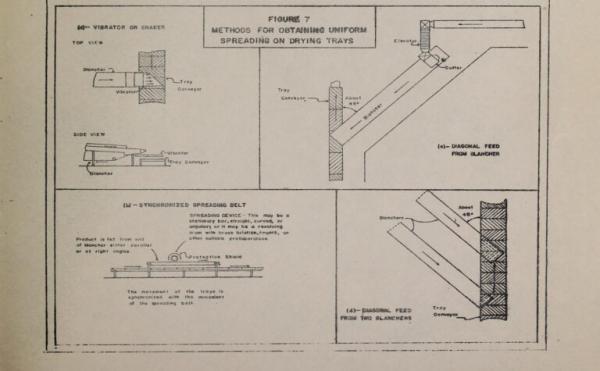

Finlay also identified how the mission of the Western Laboratory shifted in response to wartime needs. “The California facility became the nation’s center for investigations of the freezing, dehydration, and ‘dehydrofreezing’ of food. Researchers developed methods for food compression and concentration, for preserving dried fruit with sulphur dioxide and sodium bisulphite solutions, for controlling the enzymic darkening of canned and frozen apple slices, for recovering volatile fruit flavors, and for utilizing fruit pectin as a substitute for imported vegetable gums” (p. 49). Reports on research into dehydration equipment, labor requirements, processing costs, and flavor tests were issued for carrots, potatoes, rutabagas, sweet potatoes, beets, onions, cabbage, and various other foods.

Figures showing Layout of 5-Ton Dehydration Plant and Methods for Obtaining Uniform Spreading on Drying Trays. Western Regional Research Laboratory, Albany California. Bureau of Agricultural and Industrial Chemistry. Agricultural Research Administration. (1943). Information Sheet on Dehydrated Cabbage and Celery. U.S. Department of Agriculture. AIC-18. https://archive.org/details/informationsheet18unit_0

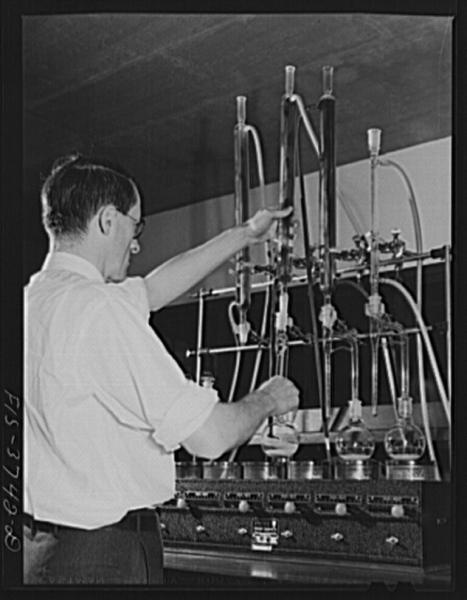

L.R. Leinbach, associate chemist, assembles the apparatus used in determining moisture content of dehydrated vegetables at the regional agricultural research laboratory. Albany, California. Russell Lee, photographer. 1942. U.S. Farm Security Administration/Office of War Information/Office of Emergency Management/Resettlement Administration Black & White Photographs. Library of Congress, Prints and Photographs. https://www.loc.gov/pictures/item/2017832266/

Blindfolding a tester of cooked dehydrated spinach at the regional agricultural research laboratory. Albany, California. Russell Lee, photographer. 1942. U.S. Farm Security Administration/Office of War Information/Office of Emergency Management/Resettlement Administration Black & White Photographs. Library of Congress, Prints and Photographs. https://www.loc.gov/pictures/item/2017832355/

The end of World War II ended the need for rapid development of dehydrated foods for military rations. At that point, the scientific staff of the Western Laboratory turned more directly to the question of flavor for foods overall, outside of a military context.

How can you measure “flavor?”

“The heart of science is measurement.”

–Erik Brynjolfsson

Director, Stanford Digital Economy Lab

Lohr, S. (2013, April 20). Big data, trying to build better workers. The New York Times. Section BU, p. 4. https://www.nytimes.com/2013/04/21/technology/big-data-trying-to-build-better-workers.html.

Once the shift to post war research was completed several chemists at the Western Laboratory turned their attention to studying the basic processes of flavor. This was a key concern, given the often bland, flavorless results of the Laboratory’s work in preserved food for military rations. Specifically, Keene Dimick and his associates Joseph Corse, Benjamin Makower, and Lloyd Ingraham started to investigate the chemical nature of the strawberry and methods for analyzing its flavor profile.

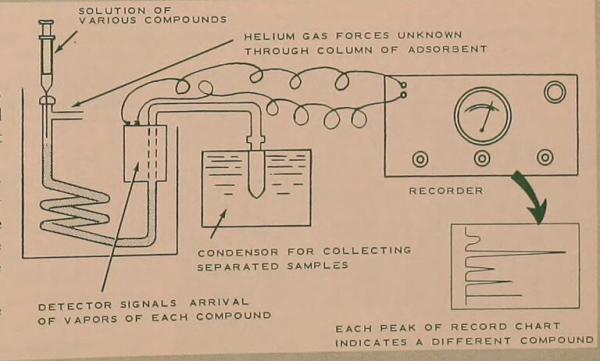

Isometric Drawing of Assembled GLPC [Gas-Liquid Partition Chromatography] Unit. Dimick, K.P. & Corse, J. (1957). The volatile flavors of strawberry. In Mitchell, Jr., J.H. & Leinen, R.J. (Eds.). Chemistry of Natural Food Flavors: A Symposium Sponsored by the National Academy of Sciences, National Research Council for Quartermaster Food and Container Institute for the Armed Forces and Pioneering Research Division, Quartermaster Research and Engineering Center, 127. United States Department of the Army. https://archive.org/details/chemistryofnatur00arme

Steadman, R.C. (1916). Fragaria: Gem. USDA Pomological Watercolor Collection. National Agricultural Library Digital Collections. https://handle.nal.usda.gov/10113/POM00004161

Identifying and replicating methods for analyzing the chemical properties of flavor in foods was not a simple task for these chemists. The central question that Dimick and his associates investigated related to the “volatiles” of food, that is “the elements that impart flavor aside from other matter, the gross material of the fruit — the water, fiber, waxes, and other stuff which comprised the bulk of the fruit’s matter, but contributed little of its flavor” (Berenstein, 2017, p. 344).

As described by a contemporary food scientist, “all researchers working on flavor volatiles of foods know how difficult this topic is; these compounds are so fragile and delicate that will change their isomerization, or will even degrade to new compounds, as soon as no optimal conditions are used for their evaluation. Therefore, extremely controlled and sophisticated methods need to be used to properly determine the real and true profiles of flavor volatile compounds. These methods include: (i) extraction of the volatile compounds from the food matrix; (ii) separation of each individual compound; (iii) identification; and, finally, (iv) quantification” (Carbonell-Barrachina, 2016).

In order to complete the essential second step of volatile separation, it was necessary for Dimick and his colleagues to develop new procedures and instruments. Building upon the foundational work of Erika Cremer and Nobel winners Archer John Porter Martin and Anthony T. James in the development of gas chromatography, the laboratory scientists built their own device for analyzing flavor volatiles. This work was described in a 1993 USDA publication.

"A chromatograph separates mixtures of substances and enables the chemist to discover what compounds are in them and in what amounts. It replaced painfully slow, one-compound-at-a-time analysis using qualitative and quantitative methods. One form of the technique, gas-liquid chromatography, enables a chemist to identify the chemical compounds present in a gas or in a substance that has been converted to gas by heating. Scientists at the Western laboratory in 1954 became the first to use gas-liquid chromatography for the study of volatile organic substances in foods. To accomplish this, they made several improvements in the technique, including increasing its resolution. This in turn led to coupling the gas chromatograph to another instrument called a fast-scan mass spectrometer. This is an electronic tool for analyzing gases that provides positive identification of mere traces of substances. The contributions of these WRRC researchers to the art of identifying the most minute constituents of complex mixtures have since been recognized by scientists all over the world."

Kelly, H.W. (1993). Always something new: A cavalcade of scientific discovery. Agricultural Research Service Miscellaneous Publication, Number 1507. U.S. Department of Agriculture. https://archive.org/details/alwayssomethingn1507kell.

Early gas-liquid chromatograph. Agricultural Research Service. U.S. Department of Agriculture.

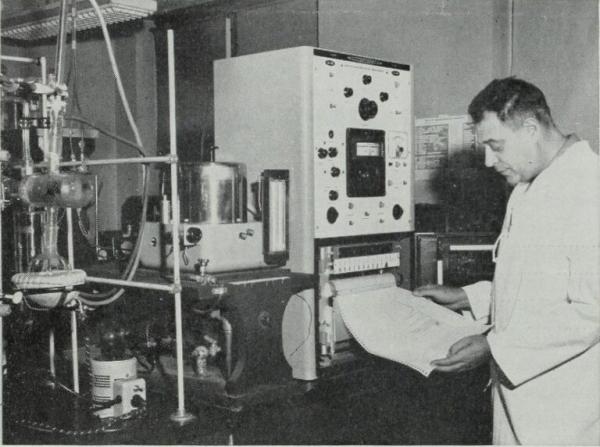

Ron Buttery, shown here adjusting a gas chromatography apparatus in 1959, was the first to identify the compound primarily responsible for the flavor of aromatic rice. Image Number D2870-1. Office of Communications. Agricultural Research Service. U.S. Department of Agriculture. https://www.ars.usda.gov/oc/images/photos/may13/d2870-1/

The “Instrumental Revolution”: The Diffusion of Gas Chromatography in Chemical Flavor Research

"The years following World War II saw the birth of the scientific instrument industry….The gas chromatographs represented the first truly automated, complex analytical instruments that did not need specially skilled scientists for their operation and could be used by practically every laboratory….We might even say that some kind of symbiosis existed between GC and the scientific instrument industry: the evolution of the former could not have happened without the involvement of the latter. A number of companies prominent today in the scientific instrumentation field started as small companies founded by some enterprising chemists starting to build gas chromatographs for the analytical chemists.”

Ettre, L.S. (2005). Fifty years of GC instrumentation. LCGC North America, 23(2), 142-148. https://www.chromatographyonline.com/view/fifty-years-gc-instrumentation-0.

This innovation was communicated and diffused to other scientists of the Agricultural Research Service.

Diagram of gas chromatograph. U. S. Department of Agriculture. Agricultural Research Service (1956). Find out with chromatography. Agricultural research, 4(10), 8-9. https://archive.org/details/CAT90891937038

[Chemist I.] Hornstein uses gas chromatography to identify chemical components of meat aromas. Agricultural Research Service. U. S. Department of Agriculture. (1962). Distinctive flavors from fat. Agricultural Research, 10(10), 14. https://archive.org/details/CAT90891937112

"Flavor research, and indeed all of chemistry, was in the midst of being radically transformed by an array of new machines. The development and technical refinement of gas chromatogaphy, mass spectrometry, infrared and ultraviolet spectroscopy, and nuclear magnetic resonance was one aspect of a broader transformation in chemistry in postwar America, when wartime advances in electronics and precision machinery converged with the needs of booming chemical and petroleum industries, crystallizing into what has been called the ‘instrumental revolution.’ Those technologies seemed to offer the key to tremendous advances in an area of chemical knowledge that had hitherto remained recondite and obscure."

p. 351

Berenstein, N. (2017). Flavor added: The sciences of flavor and the industrialization of taste in America. Unpublished doctoral dissertation. University of Pennsylvania. https://repository.upenn.edu/edissertations/2715.

"The western laboratory, now known as the Western Regional Research Center (WRRC), was recognized with two ACS [American Chemical Society] National Historic Chemical Landmark awards. The first was for the groundbreaking frozen food research during the late 1940s through the early 1960s. These time-temperature tolerance studies provided the scientific basis for the reproducible, safe production of high quality, nutritious frozen foods. In close collaboration with the frozen food industry, WRRC scientists studied changes in a wide range of frozen foods as they proceeded through the distribution system to determine deviations that were acceptable or not for high quality consumer products. The scientists developed mathematical models to predict the stability and quality of frozen foods over time. They also discovered that 0°F is the critical temperature to maintain stability in most frozen foods. They established analytical methods for measuring 'quality' and stability periods for frozen foods. “Dehydrofreezing,” a process of partial dehydration prior to freezing that results in significant savings and quality improvements, was invented. Finally, individual quick blanching (IQB) processes were developed for high quality frozen vegetables.

The second award recognizes WRRC’s world-renowned research in flavor chemistry."

McHugh, T. (2015). USDA’s research labs—Past, present, and future. Food Technology Magazine, 69(1). https://www.ift.org/news-and-publications/food-technology-magazine/issues/2015/january/columns/processing.

The Western Regional Research Center in Albany, California is still actively pursuing research projects to advance the state of agricultural science and serve the American people. Some of their recent projects include novel uses of almond shells and mushroom-stalk waste, processes for freezing foods and reducing food waste, pathogen detection, and development of the lilac lime. More information about the current work of the center is available on its news page: https://www.ars.usda.gov/pacific-west-area/albany-ca/wrrc/news/.

Emily Marsh, Ph.D., MLS

The U.S. Department of Agriculture published many materials documenting the scientific work of the Western Regional Research Laboratory. Here is a sample of these publications held by the National Agricultural Library.

U.S. Department of Agriculture (1939). Regional research laboratories. Department of Agriculture. U.S. Department of Agriculture.

https://archive.org/details/CAT10504947.

"In the discussion of the appropriations for the four regional research laboratories, Congress raised certain questions regarding the present status of research in the field of industrial utilization of agricultural commodities and provided that 'not to exceed $100,000 shall be available under the provisions of sections 202 (a) to 202 (e), inclusive, of said act [the Agricultural Adjustment Act of 1938] to conduct a survey to determine the location of said [regional research] laboratories and the scope of the investigations to be made and to coordinate the research work now being carried on.'” (Public, No. 644, 75th Cong., H. R. 10238.

In accordance with this provision in the Appropriation Act, a special survey committee was appointed, with the following instructions:

(1) To conduct a survey of all research activities relating to the industrial utilization of agricultural products in the four regional areas to be served by the regional laboratories, such survey to include a study of the research projects of the Department of Agriculture and other Federal agencies, the State experiment stations, educational institutions, privately endowed research institutions, commercial consulting research laboratories, and the research laboratories maintained by industries based wholly or in part on utilization of agricultural raw materials, and report their findings to the Department.

(2) To assemble facts bearing upon suitability of proposed laboratory locations and make report thereon to the Department.

(3) To make recommendations to the Department as to the scope of investigations to be undertaken in these laboratories, and as to ways in which the research recommended may be coordinated with other activities in the same field."

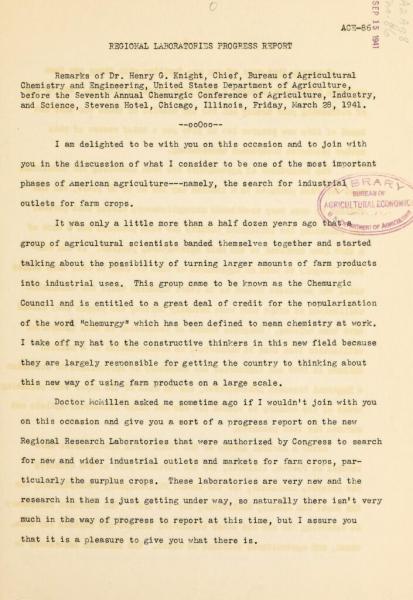

Knight, H.G. (1941). Regional laboratories progress report. U.S. Department of Agriculture. ACE-86.

https://archive.org/details/regionallaborato86knig.

"The Department of Agriculture has been searching for industrial uses for farm products in a limited way for 25 or 30 years, and has chalked up some very creditable accomplishments during that period. But searching for industrial outlets for farm products was a sort of a side line compared to the main agricultural program. It was confined largely to work on byproducts or what we used to call farm wastes until the surpluses forced us to start thinking about the profitable utilization of crops that were actually hurting the people they should have been helping. Congress became so interested in this industrial utilization idea that it authorized an appropriation of 4 million dollars in 1938 and instructed the Secretary of Agriculture to establish 4 Regional Research Laboratories, one in each of the major farm producing areas of the country to search for new and wider industrial outlets and markets for farm products.

After a careful survey of the field these laboratories were located at Peoria, Illinois, for the northern part of the country; New Orleans, Louisiana, for the South; Philadelphia, Pennsylvania, for the east; and Albany, California, for the west. The Northern laboratory is searching for new and wider industrial outlets and markets for corn, wheat, and agricultural residues or waste. The Southern Laboratory is working on cotton, sweetpotatoes, and peanuts; the Eastern Laboratory on apples, tobacco, milk products, potatoes, vegetables, animal fats and oils, hides, skins and tanning materials; and the Western Laboratory on wheat, potatoes, apples, vegetables, fruits, alfalfa, and poultry products and byproducts."

U.S. Department of Agriculture. Agricultural Research Administration. Bureau of Agricultural and Industrial Chemistry (1941). Information on the regional laboratories for research on utilization of farm products. U.S. Department of Agriculture. ACE-41 Revised.

https://archive.org/details/informationonreg41unit.

"Methods used in the Western Regional Research Laboratory for the extraction, isolation, purification, and analysis of pectic substances are described in this publication. Procedures are presented for the extraction of total pectic substances and for the extraction, isolation, and purification of undegraded pectin for characterization. Specific directions are given for the determination of ammonia, moisture, ash, equivalent weight, methoxyl, anhydrouronic acid, acetyl, viscosity, jelly grade, setting time, and specific optical rotation, methods of assay for pectinesterase (PE) and polygalacturonase (PG) are included. Later napes contain references and a list of current nomenclature of pectic substances and enzymes.

The establishment of four regional laboratories was authorized by Section 202 of the Agricultural Adjustment Act of 1938. Under this section the Secretary of Agriculture was authorized and directed to 'establish, equip, and maintain four regional research laboratories, one in each major farm producing area, and, at such laboratories to conduct researches into and to develop new scientific, chemical, and technical uses and, new and extended markets and outlets for farm commodities arid products and byproducts thereof. Such research and development shall be devoted primarily to those farm commodities in which there are regular or seasonal surpluses, and their products and byproducts.' The Bureau of Agricultural Chemistry and Engineering administers the laboratories for the Department."

Van Arsdel, W.B. (1941). The Western Regional Laboratory for research on utilization of farm products. Engineering and Development Division. Western Regional Research Laboratory. Bureau of Agricultural Chemistry and Engineering. U.S. Department of Agriculture. ACE-75.

https://archive.org/details/westernregionall75vana

"The program of this conference is symptomatic of the troubles and problems that have increasingly beset American agriculture during the past twenty years. Certainly the idea of having such a symposium as this would not have occurred to anyone during the World War. At that time the urgency was to make two blades of wheat grow where one grew before. In this European War we are wondering what to do with the second blade we have succeeded so well in growing. Crop surpluses are, I take it, one of the chief concerns of this conference.

It is generally agreed that three major factors have operated to bring about surplus conditions- -the decline of foreign trade, advances in science and technology, and widespread unemployment.

Mr. Milo Perkins, of the Surplus Marketing Administration, writing in December ‘Harper's Magazine’, says of foreign trade: ‘Troubles for farmers who have been producing for the export market are likely to continue for some years…. The pressure of our present surpluses is likely to lead to a demand for economic appeasement-feeding and clothing a Hitler-dominated Europe... The only lasting cure is to build up domestic consumption to replace the vanished foreign demand.’

The effect of advances in the science of farming has recently been the subject of careful study by the Bureau of Agricultural Economics. Their publication, ‘Technology on the Farm’, concludes that it is neither possible nor desirable to turn the clock backward. We shall continue to mechanize farms, displace farm labor, develop higher yielding crops, and stamp out disease. We now know how to assure abundance of food and clothing for any probable population of the United States; but we must learn how to handle that new thing in mankind's history -- abundance."

Bureau of Agricultural and Industrial Chemistry. Agricultural Research Administration. U.S. Department of Agriculture (1947). Exhibit pictures from the four regional research laboratories. U.S. Department of Agriculture. Miscellaneous Publication Number 617.

https://archive.org/details/exhibitpicturesf617unit

"WESTERN REGIONAL RESEARCH LABORATORY

Vegetable (asparagus) waste utilization for production of antibiotics... 46

Production of subtilin... 47

Low-methoxyl pectin manufacture by acid precipitation... 48

Low-methoxyl pectin food products... 49

Yeast from fruit wastes... 50

Fibers from feathers... 51

Storage life of dehydrated whole egg... 52

Effect of in-package desiccation on the storage life of dehydrated vegetables... 53

Velva Fruit... 54"

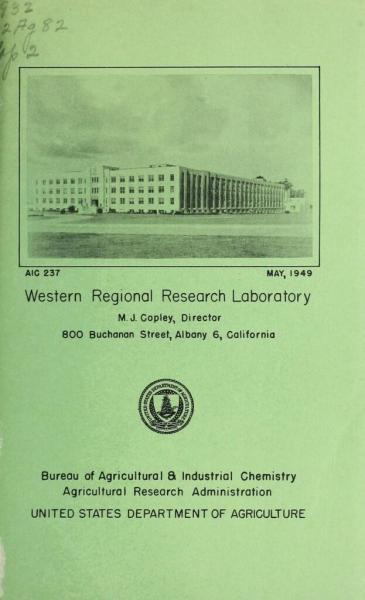

Bureau of Agricultural and Industrial Chemistry. Agricultural Research Administration. U.S. Department of Agriculture (1949). Western Regional Research Laboratory. U.S. Department of Agriculture. AIG 237.

https://archive.org/details/westernregionalr237unit.

"The four Regional Research Laboratories are parts of the Bureau of Agricultural and Industrial Chemistry. In addition the Bureau includes a number of other research groups….

The buildings and facilities of the four regional laboratories are closely similar. Each building has three stories and basement and is built in the form of a U with administrative activities in the base of the U and research work in the two wings. In one wing there is a large room extending the full height of the building where engineering laboratory operations in some cases on a pilot plant scale are conducted.

The Western Laboratory has about 100 standard-sized laboratory rooms. The basement contains specialized laboratories, store rooms, and mechanical shops."

Bureau of Agricultural and Industrial Chemistry. Agricultural Research Administration. U.S. Department of Agriculture. (1949). Western Regional Research Laboratory: List of patents. U.S. Department of Agriculture. AIC-244

https://archive.org/details/westernregionalr244unit.

"United States Department of Agriculture

Agricultural Research Administration

Bureau of Agricultural and Industrial Chemistry

WESTERN REGIONAL RESEARCH LABORATORY

800 Buchanan St.

Albany 6, California

List of Patents

The patents listed below are available for licensing, on a royalty-free basis. Those marked ‘Dedicated’ have been dedicated to the people of the United States by the inventors and require no licenses. The others have been assigned to the United States Government as represented by the Secretary of Agriculture and are available for licensing on a royalty-free, non-exclusive, revocable, and non-transferable basis."

Owens, H.S. (1952). Research resources of Bureau of Agricultural and Industrial Chemistry in four regional research laboratories and eleven other branch stations. Agricultural Research Administration. U.S. Department of Agriculture. AIC 341.

https://archive.org/details/researchresource341owen.

"The Bureau of Agricultural and Industrial Chemistry is one of the Research Bureaus in the Agricultural Research Administration of the U. S. Department of Agriculture. Its facilities are designed to solve problems concerned with the utilization of a wide variety of agricultural commodities and its personnel are experienced in research in chemistry: biochemistry, microbiology, physics, pharmacology, food and textile technology, engineering and other related sciences and technologies. The scope of the Bureau's technical resources in equipment and personnel is outlined in this pamphlet for the information of interested research agencies."

Owens, H.S., McCready, R.M., Shepherd, A.D., Schultz, T.H., Pippen, E.L., Swenson, H.A., Miers, J.C., Erlandsen, R.F., & Maclay, W.D. (1952). Methods used at Western Regional Research Laboratory for extraction and analysis of pectic materials. Agricultural Research Administration. U.S. Department of Agriculture. AIC-340.

https://archive.org/details/methodsusedatwes340owen/

"Methods used in the Western Regional Research Laboratory for the extraction, isolation, purification, and analysis of pectic substances are described in this publication. Procedures are presented for the extraction of total pectic substances and for the extraction, isolation, and purification of undegraded pectin for characterization. Specific directions are given for the determination of ammonia, moisture, ash, equivalent weight, methoxyl, anhydrouronic acid, acetyl, viscosity, jelly grade, setting time, and specific optical rotation, methods of assay for pectinesterase (PE) and polygalacturonase (PG) are included. Later pages contain references and a list of current nomenclature of pectic substances and enzymes."

Agricultural Research Service. U.S. Department of Agriculture. (1964). Proceedings of the conference on advances in flavor research: Held at New Orleans, Louisiana, March 25 and 26, 1963. Agricultural Research Service. U.S. Department of Agriculture. ARS-72-29.

https://archive.org/details/proceedingsofcon7229unit

"The Conference on Advances in Flavor Research was sponsored by the Southern Utilization Research and Development Division in cooperation with the southern agricultural experiment stations. Its purpose was to strengthen liaison between the Southern Division and the experiment stations, and to exchange information on important subjects of joint interest.

In prior years attendance at the annual conference of these cooperating agencies has been confined to their representatives. The topic of flavor, however, aroused interest throughout the country; therefore, the Southern Division joined the southern experiment stations in encouraging the attendance of anyone interested in the area of flavor research.

This report which was compiled Leah C. Berardi and Beatrice A. Sharar of this Division, summarizes the statements of the various speakers during the conference, and gives an account of the discussions which followed."

References

Agricultural Adjustment Act of 1938. Title 7 U.S.C Chapter 35. §1292. New uses and markets for commodities (1938, February 16). https://uscode.house.gov/view.xhtml?path=/prelim@title7/chapter35&edition=prelim.

American Chemical Society (2013, August 29). Flavor chemistry research: USDA ARS Western Regional Research Center. Washington, D.C.: American Chemical Society. https://www.acs.org/content/dam/acsorg/education/whatischemistry/landmarks/usda-flavor-chemistry/flavors-brochure.pdf.

Berenstein, N. (2017). Flavor added: The sciences of flavor and the industrialization of taste in America. Unpublished doctoral dissertation. University of Pennsylvania. https://repository.upenn.edu/edissertations/2715.

Carbonell-Barrachina, A.A. (2016). Introduction to the special issue of Foods, Flavour Volatiles of Foods. https://www.mdpi.com/journal/foods/special_issues/flavour_volatiles.

Crocker, E.C. (1937). Measuring food flavors. Journal of Food Science, 2(3), 273-286. https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1365-2621.1937.tb16518.x.

Dimick, K.P. & Corse, J. (1957). The volatile flavors of strawberry. In Chemistry of Natural Food Flavors: A Symposium Sponsored by the National Academy of Sciences, National Research Council for Quartermaster Food and Container Institute for the Armed Forces and Pioneering Research Division, Quartermaster Research and Engineering Center, 123-132. United States: Department of the Army. https://archive.org/details/chemistryofnatur00arme.

Ettre L. S. (2002). The early development and rapid growth of gas chromatographic instrumentation in the United States. Journal of chromatographic science, 40(8), 458–472. https://doi.org/10.1093/chromsci/40.8.458.

Ettre, L.S. (2005). Fifty Years of GC Instrumentation. LCGC North America, 23(2), 142-148. https://www.chromatographyonline.com/view/fifty-years-gc-instrumentation-0.

Finlay, M.R. (1990). The industrial utilization of farm products and by-products: The USDA Regional Research Laboratories. Agricultural History, 64(2), 41-52. https://www.jstor.org/stable/3743795.

Hanson, R.L. (1940). Description of regional research laboratories. Bureau of Agricultural Chemistry and Engineering. U.S. Department of Agriculture. ACE-33. https://archive.org/details/descriptionofreg33hans.

International Organization for Standardization (2008). Sensory analysis — Vocabulary. (ISO Standard No. 5492:2008). https://www.iso.org/standard/84513.html.

International Organization of the Flavor Industry (n.d.). IOFI — Global leadership in the work of flavors. Washington, D.C.: International Organization of the Flavor Industry. https://cdn2.assets-servd.host/erratic-warthog/production/Documents/IOFI-Company-brochure-vs-06-LR-SINGLE-PAGE.pdf.

Kelly, H.W. (1993). Always something new: A cavalcade of scientific discovery. Agricultural Research Service, Miscellaneous Publication, Number 1507. U.S. Department of Agriculture. https://archive.org/details/alwayssomethingn1507kell.

Lohr, S. (2013, April 20). Big data, trying to build better workers. The New York Times. Section BU, 4. https://www.nytimes.com/2013/04/21/technology/big-data-trying-to-build-better-workers.html.

McHugh, T. (2015). USDA’s research labs—Past, present, and future. Food Technology Magazine, 69(1). https://www.ift.org/news-and-publications/food-technology-magazine/issues/2015/january/columns/processing.

Mouritsen, O.G. (2015). The science of taste. Flavour, 4(18). https://doi.org/10.1186/s13411-014-0028-3.

Mouritsen, O.G. & Styrbaek, K. (2017). Mouthfeel: How texture makes taste. New York: Columbia University Press.

Pence, C. (2022). The tongue map and the spatial modulation of taste perception. Current Research in Food Science, 5, 598-610. https://doi.org/10.1016/j.crfs.2022.02.004.

Perszyk, E.E., Stewart, B., & Roland, H.R. (2019, 28 August). Psychological perspectives on taste. Oxford Bibliographies. https://www.oxfordbibliographies.com/view/document/obo-9780199828340/obo-9780199828340-0249.xml.

Shepherd, G.M. (2006). Smell images and the flavour system in the human brain. Nature, 444, 316-321. https://doi.org/10.1038/nature05405.

Shepherd, G.M. (2015). Neuroenology: How the brain creates the taste of wine. Flavour, 4(19). https://doi.org/10.1186/s13411-014-0030-9.

Spence, C., Smith, B., & Auvray, M. (2014). Confusing tastes with flavours. In Stokes, D., Matthen, M., & Briggs, S. (Eds.). Perception and Its Modalities, 247-279. Oxford: Oxford University Press.

Van Arsdel, W.B. (1941). The Western Regional Laboratory for research on utilization of farm products. Engineering and Development Division. Western Regional Research Laboratory. Bureau of Agricultural Chemistry and Engineering. U.S. Department of Agriculture. ACE-75. https://archive.org/details/westernregionall75vana.

An official website of the United States government.

An official website of the United States government.